product description:

The CNC roll crescent groove machine tool has the advantages of high degree of automation, high machining accuracy, high cutting efficiency, safe and reliable operation, etc. The machine tool meets the requirements of groove milling, slot-hopping, and lettering in one clamping, and does not require secondary clamping of the roll. The machine bed is a heavy-duty roll machining machine with three parallel guide rails. The width of the bed must reach 910mm, and the width of the saddle must reach 810mm, so as to ensure sufficient rigidity and anti-vibration performance of the machine tool as a whole, so as to be suitable for milling high-hardness tungsten carbide roll rings and high-speed steel. roll.

technical parameter:

Maximum diameter of processing roll

500mm

Minimum diameter

50mm

Maximum length of processing roll

2500mm

Maximum length of processing roll surface

1800mm

Processing crescent socket specifications

Φ6~Φ50

Machining crescent alveolar beta angle

any

Processing crescent grooves

any

Lateral movement speed (X axis)

0~6000mm/min

Workpiece rotation speed (Y axis)

0~30rpm

Swing head rotation speed (Z axis)

0~50rpm

Flying cutter milling speed (A axis)

0~600rpm

Milling head motor power rated speed

1.5Kw 2500rpm

Cooling Pump Motor

AB25-90W

Control System

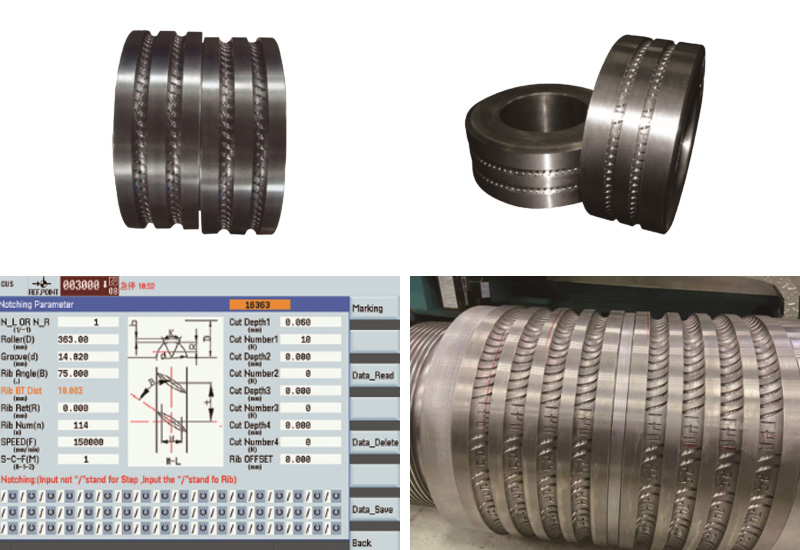

Siemens 808D

Servo motor rated power

X-axis 1.5kw

Y-axis 2.5kw

Z axis 1.5kw

A-axis 3.0kw

Minimum programming

0.001

Longitudinal magnetic scale effective measuring length

2000mm

Grating accuracy

0.005mm

Chuck form

four claws

Chuck diameter

400mm

Machine power supply

380V,50HZ;15KVA

Dimensions

4500×1700×2000mm

Machine tool net

6.0T

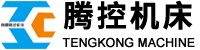

Processing example:

Address:No. 44, Guangsheng Road, Gangzha District, Nantong City

Hotline:+86-13901488857

Mail:xhongwei@163.com

Website:www.tklathe.com